In this study, the researchers investigated the performance of Organic Based Stabilizer (OBS) compared to traditional Lead-Based Stabilizer (Pb) and Calcium-Zinc Stabilizer (CaZn) in formulating rigid PVC pipes.

The results showed that the organic PVC thermal stabilizer (OBS) has a more favorable thermal performance by providing better processability, more uniform fusion behavior, and higher initial color stability than Pb and CaZn. Also, repeated process cycles increased gelation without having a negative effect on the impact strength or Thermal Stability of PVC.

OBS significantly increased thermal stability by inhibiting autocatalytic thermal degradation and reducing the rate of dehydrochlorination.

Overall, this Eco-Friendly Lead-Free PVC Stabilizer is a suitable and non-toxic alternative to lead stabilizers in PVC pipe production.

Understanding Polyvinyl Chloride (PVC)

- Polyvinyl Chloride (PVC) is a widely used commodity plastic that offers a variety of mechanical and thermal properties in both rigid and flexible forms. The construction, sewage, water supply, and drainage industries use PVC pipes because the material offers durability, corrosion resistance, and a reasonable price.

- However, PVC is unstable at process temperatures and undergoes thermal degradation (Thermal Degradation of PVC) when it reaches 170–180 ° C. During this process, the reaction separates chlorine and hydrogen from the chain and releases HCl gas, which darkens the color and deteriorates the mechanical and physical properties of the material.

- To prevent this phenomenon, manufacturers add PVC heat stabilizers to increase the material’s thermal stability and resistance to degradation.

- In recent years, environmental regulations have prompted manufacturers to consider using lead-free stabilizers. Among the alternatives, Calcium-Zinc Stabilizer (CaZn) and Organic Stabilizer (OBS) have the greatest potential for producing safer and more stable PVC Pipes.

Materials and Methods

- Researchers used suspension-type PVC resin with K=66, along with calcium carbonate filler and three different types of stabilizers: Pb, CaZn, and OBS. Organic stabilizer (OBS) is a single-component type and shows better properties in improving Thermal Stability due to its specific organic structure.

- The researchers processed the samples at 180°C in a twin roller and then performed TGA, DSC, and torque rheometer tests to investigate thermal behavior and color stability.

Results and Discussion of the Performance of Organic Thermal Stabilizer (OBS) in PVC Pipes Compared to Pb and CaZn

- Rheological Behavior and Fusion Process: Observations showed that the fusion time for PVC/OBS compounds was longer but more stable than that of Pb and CaZn compounds. The fusion torque in PVC/OBS was in a range that indicated the stability of the process at high temperature.

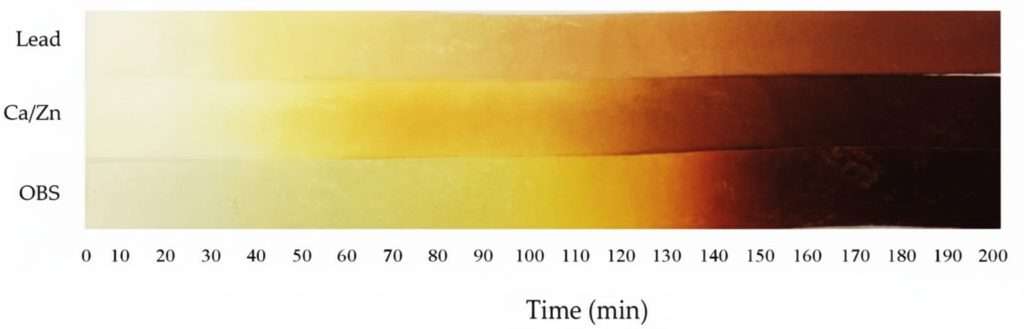

- Static Thermal Stability: In the thermal test at 180°C, the PVC/OBS compound remained colorless for 50 minutes, while PVC/Pb and PVC/CaZn started to change color in 30 minutes and 40 minutes. This shows that Organic Based Stabilizer has a significant effect on maintaining the original color and preventing Thermal Degradation.

- Thermal Decomposition Analysis: TGA (Thermogravimetric Analysis) studies showed that the onset temperature of degradation in PVC/OBS is about 297°C, which is higher than that of Pb (295°C) and CaZn (293°C). Also, OBS showed a higher activation energy, which means higher resistance to thermal degradation.

- Kinetic Analysis: According to Kissinger and Flynn–Wall–Ozawa (FWO) methods, the activation energy of the dehydrochlorination process in PVC/OBS was the highest (about 148 to 155 kJ/mol), which indicates higher thermal stability.

- Effect of repeated processing cycles on mechanical properties: In repeated processing cycles (up to 5 times), the gelation degree in PVC/OBS showed the highest stability. The impact strength of PVC/OBS samples was also higher than PVC/Pb and PVC/CaZn, which is a very desirable feature for industrial PVC pipes.

- Heat Deflection Temperature (HDT): PVC/OBS had an HDT of 76°C, which is slightly higher than PVC/Pb (75°C) and PVC/CaZn (74.5°C). This indicates that the organic stabilizer can maintain its structural stability at higher operating temperatures.