Polyvinyl chloride (Polyvinyl Chloride – PVC) is one of the most important thermoplastic polymers in the plastics industry. Pure PVC is a white, rigid, and brittle material. After polyethylene (PE) and polypropylene (PP), PVC ranks as the third most widely used polymer worldwide, with an annual global production of approximately 40 million tons. The chemical structure of PVC has the formula (C₂H₃Cl)ₙ, and manufacturers produce it by polymerizing vinyl chloride monomer (VCM). The degree of polymerization of PVC typically ranges from 300 to 1500. The presence of about 57 wt.% chlorine in the polymer structure reduces its dependence on hydrocarbon resources.

Introduction

PVC is generally classified into two main types: rigid PVC (uPVC or rigid PVC) and flexible PVC (plasticized PVC). Rigid PVC contains no plasticizers, and the construction industry uses it extensively to produce pipes, profiles, sheets, and panels. Manufacturers obtain flexible PVC by adding plasticizers to rigid PVC; its high flexibility allows it to replace rubber effectively in many applications. Common applications of flexible PVC include plumbing systems, electrical cable insulation, PVC artificial leather, PVC flooring, and industrial hoses.

Polyvinyl chloride is a thermoplastic polymer with relatively low thermal stability. Therefore, the use of PVC additives is essential to improve its mechanical, thermal, and chemical properties. Unmodified PVC undergoes thermal degradation at elevated temperatures, releasing hydrogen chloride (HCl), which accelerates further degradation. For this reason, manufacturers must modify PVC by adding heat stabilizers, lubricants, fillers, impact modifiers, pigments, and plasticizers. These additives play a critical role in the PVC compounding process.

PVC resins are classified according to their K-value, which reflects molecular weight and degree of polymerization.PVC with a K-value of 57 has a relatively low molecular weight, and manufacturers commonly use it in packaging films, blown sheets, bottles, and injection-molded parts. In contrast, PVC with a K-value between 70 and 75 provides higher mechanical strength but challenges processors during fabrication; manufacturers therefore use it in PVC pipes, construction profiles, high-performance electrical cables, and industrial flooring. Manufacturers use emulsion PVC in the form of plastisols or latex for coatings, multilayer films, and battery separators.

Materials and Methods

2.1. Dry Blending of PVC

In the dry blending (Dry Blend) method, manufacturers use high-speed mixers to uniformly mix PVC resin with various polymer additives, producing a homogeneous powder. Manufacturers widely apply this method in PVC compound production.

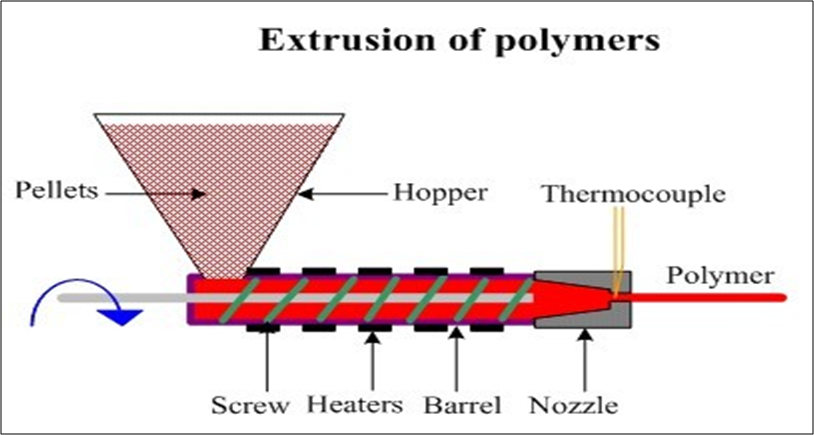

2.2. Extruder Mixing

In the PVC extrusion process, operators feed raw materials into an extruder, where the machine melts and mixes them. The material then passes through heating zones, undergoes controlled cooling, and is pelletized into PVC granules suitable for further processing steps such as injection molding and blow molding.

PVC Additives

3.1. PVC Plasticizers

Plasticizers are the most important additives for flexible PVC. The addition of plasticizers increases flexibility, reduces hardness, and improves the processability of PVC.

3.1.1. Primary Plasticizers

Primary PVC plasticizers, such as dioctyl phthalate (DOP), mix very well with PVC resin, and manufacturers widely use them to produce very soft products, including hoses, electrical cables, and medical PVC items.

3.1.2. Secondary Plasticizers

Manufacturers mainly use secondary plasticizers, such as chlorinated paraffin wax (CPW), to reduce the cost of PVC compounds and achieve economic benefits in PVC formulations.

3.1.3. Plasticizers for Medical Applications

In the medical industry, manufacturers use medical-grade PVC plasticizers such as DOP, TOTM, BTHC, and DnDP to produce blood bags, IV sets, and medical PVC tubing.

3.2. PVC Stabilizers

PVC heat stabilizers and PVC light stabilizers are essential for preventing thermal and UV-induced degradation of polyvinyl chloride during processing and service life.

3.3. PVC Fillers

Manufacturers add PVC fillers such as calcium carbonate, titanium dioxide (TiO₂), talc, and nano-fillers to reduce formulation costs and enhance the mechanical properties of PVC.

3.4. PVC Impact Modifiers

Manufacturers add PVC impact modifiers, including ABS and CPE, to rigid PVC formulations to significantly improve impact resistance and toughness.

3.5. PVC Pigments

Organic and inorganic PVC pigments must exhibit high thermal stability, good dispersion, and excellent lightfastness to ensure long-term color performance.

Applications of PVC

4.1. PVC in Piping Systems

PVC pipes are widely used in industrial and building piping systems due to their excellent chemical resistance, low weight, and long service life.

4.2. PVC in Construction

PVC construction products include door and window profiles, flooring materials, suspended ceilings, electrical insulation components, and decorative panels.

4.3. PVC in Medical Applications

Medical-grade PVC is extensively used in disposable medical devices due to its biocompatibility, durability, chemical stability, and cost-effectiveness.

Conclusion

Polyvinyl chloride (PVC) is one of the most widely used industrial polymers. Through the incorporation of appropriate additives, PVC can be transformed into an engineered material with diverse applications in construction, medical devices, packaging, and electrical industries. Continued research and development of advanced PVC formulations and innovative additives will further expand the performance and application range of this versatile polymer.