Calcium stearate, a salt derived from stearic acid, is a compound widely used in several industries due to its versatile applications. Notably, in the construction sector, calcium stearate holds a special place for its unique properties, making construction materials more durable and efficient. This article explores the applications, benefits, and nuances of calcium stearate’s use in the construction world.

Chemical Properties & Production

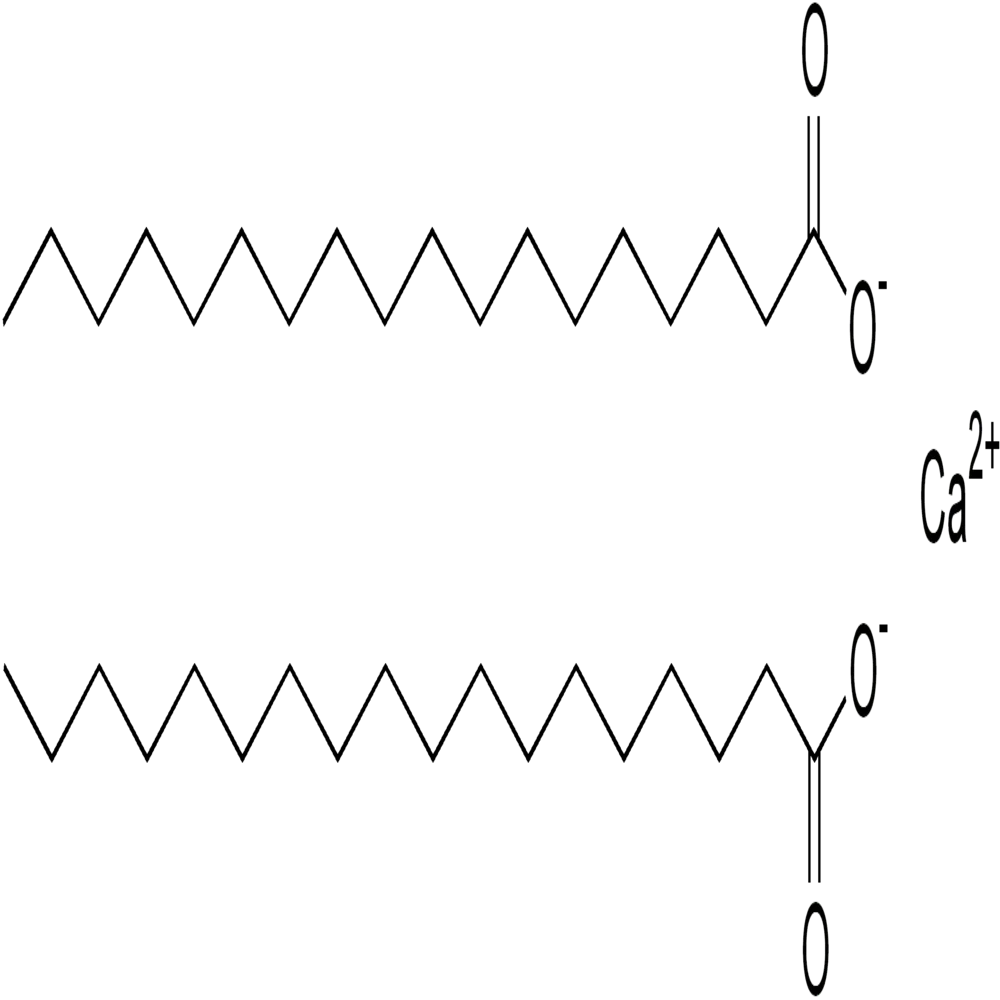

Calcium stearate (Ca(C18H35O2)2) is a waxy substance, water-insoluble, and possesses a white appearance. It’s produced by the reaction between lime and stearic acid or from salts of stearic acid. The production is highly controlled to achieve the quality required for construction applications.

Applications in Construction (Calcium stearate Ca)

- Water Repellent:. Widely used in construction for its hydrophobic characteristics. When added to concrete or plaster, it makes them water-repellent, thereby increasing their lifespan and durability.

- Plasticizer for Mortar & Concrete: Calcium stearate acts as a plasticizer, making the mixture more workable and lessens water content. This ensures a stronger final product and decreases the possibility of cracks.

- Mold Release Agent: For prefabricated construction elements, calcium stearate acts as a mold release agent. It ensures easy removal of the product from its mold, minimizing damage and enhancing the finish.

- Paint and Coatings: It serves as a stabilizer in paints and coatings, preventing them from separating, settling, or spoiling. This ensures consistent color and texture throughout.

- Roofing: In roofing materials, calcium stearate acts as an anti-sticking agent, preventing different layers from sticking to each other.

- Durability: Calcium stearate increases the lifespan of construction materials, reducing maintenance costs.

- Workability: Makes mortars and concretes more malleable and easier to work with, saving time and effort.

- Economic: Reducing the need for repairs and replacements, calcium stearate saves money in the long run.

- Environmental:. Given its derivation from natural sources, calcium stearate stands out as a more eco-friendly option compared to numerous other additives in the construction industry.

Considerations and Drawbacks

- Quality Variation: The quality of calcium stearate can vary based on its production method, leading to inconsistent results if not properly sourced.

- Overuse: Excessive use can lead to weakening of the construction material. It’s crucial to maintain the right balance.

- Environmental Concerns:.Even though calcium stearate originates from natural sources, the methods used in its extraction and refinement can pose environmental challenges.

Conclusion

The construction industry greatly relies on calcium stearate, highlighting its indispensable role. Its myriad applications ranging from water repellency to acting as a plasticizer make it an essential additive in modern construction. However, like all materials, careful sourcing, and proper application are vital to harnessing its full potential. When used judiciously, calcium stearate can significantly enhance the quality and longevity of construction projects.