Polyvinyl Chloride (PVC) is a ubiquitous polymer with extensive applications in various industries, including construction, healthcare, and packaging. While its versatility is commendable, the conventional plasticizers like phthalates that are often used to soften PVC are under scrutiny due to their potential environmental and health impacts. Amidst the rising concerns, Epoxidized Soybean Oil (ESO) has emerged as an eco-friendly alternative. This article delves into the role of ESO in PVC film applications, its advantages over traditional plasticizers, and its impact on environmental sustainability.

What is Epoxidized Soybean Oil?

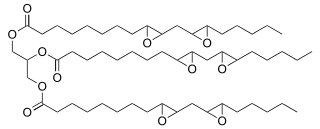

Epoxidized Soybean Oil (ESBO) originates from oxidized soybean oil and falls under the category of organic ester compounds. The production process involves epoxidizing the double bonds in soybean oil, a reaction facilitated by a form of peroxide. In PVC formulations, ESO serves mainly as a plasticizer and stabilizer, thereby enhancing the polymer’s effectiveness across various applications.

Role of ESO in PVC Film

Plasticization

PVC is inherently a rigid material, requiring the use of plasticizers for flexibility. ESBO, when added to PVC, diffuses into the polymer matrix, increasing its elasticity and reducing rigidity. In PVC films used for packaging, this malleability is a key advantage.

Thermal Stability

PVC products frequently encounter high temperatures, either during their manufacturing process or in their end-use applications. Epoxidized Soybean Oil ESBO demonstrates excellent thermal stability, ensuring that the PVC films remain durable and effective even at elevated temperatures.

UV Resistance

For agricultural films, UV resistance is key. Epoxidized Soybean Oil (ESBO) enhances the UV stability of PVC films, thereby increasing their durability in outdoor settings.

Advantages Over Conventional Plasticizers

Non-Toxicity (ESBO in PVC Film)

While phthalates, frequently used in PVC, have been linked to health concerns like endocrine disruption, Epoxidized Soybean Oil (ESBO) stands out as a bio-based and non-toxic alternative. This makes it a safer choice for consumer items such as food packaging films.

Biodegradability

Being derived from plants, it offers greater biodegradability than its synthetic counterparts, contributing to less long-term environmental pollution.

Lower Migration

Epoxidized Soybean Oil (ESBO) exhibits lower migration rates compared to traditional plasticizers, thereby retaining its properties in the PVC matrix for extended periods. This results in longer-lasting PVC films.

Cost-Effectiveness

Though initially more expensive, the lower migration and reduced need for stabilizers make ESO a cost-effective solution in the long run.

Environmental Impacts (ESBO in PVC Film)

Carbon Footprint

Compared to fossil fuel-based plasticizers, Epoxidized Soybean Oil (ESBO) comes from renewable resources, which significantly lowers the carbon footprint of its production.

Waste Reduction

Since Epoxidized Soybean Oil (ESBO) is biodegradable, PVC films incorporating it contribute less to landfill waste, further endorsing its environmental benefits.

Regulatory Perspective

Governments worldwide are tightening regulations concerning the use of toxic substances in consumer products. Epoxidized Soybean Oil (ESBO) complies with most global safety standards, including the U.S. Food and Drug Administration (FDA) for food contact materials.

Future Prospects

With advancements in green chemistry, the efficiency of Epoxidized Soybean Oil (ESBO) as a plasticizer is likely to improve further, providing an even stronger case for its adoption. Expectations point to an exponential growth in market demand for eco-friendly plasticizers such as ESO in the near future.

Conclusion (ESBO in PVC Film)

Epoxidized Soybean Oil has proven to be a viable, eco-friendly alternative to traditional plasticizers in PVC films. Its superior performance characteristics, coupled with its environmental benefits, make it an increasingly popular choice in the polymer industry. Amidst the changing regulatory landscape and growing awareness of environmental sustainability, ESO in PVC film represents a step towards greener and safer plastics.