Polyvinyl Chloride, commonly known as PVC, is one of the most widely used synthetic materials in the world today. Its applications are diverse, spanning multiple industries such as construction, healthcare, and textiles. Among its many uses, PVC plays an especially crucial role in the manufacture of pipes and fittings. One often-overlooked element in this process is the PVC granule—a fundamental building block that dramatically influences the quality, functionality, and sustainability of the finished products. This article aims to shed light on the importance of PVC granules in the manufacturing process, outlining their roles, benefits, and challenges.

What are PVC Granules?

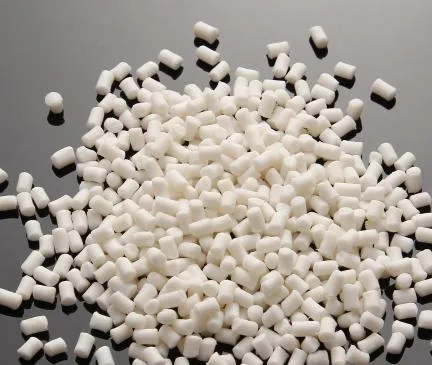

PVC granules are small, generally uniform particles created through the polymerization of vinyl chloride. These granules serve as the raw material for a variety of PVC-based products, from cable insulation to inflatable structures, and, of course, pipes and fittings. In granulated form, these particles are easier to manage and exhibit better flow characteristics during manufacturing. This is particularly important for crafting complex shapes such as pipes and fittings.

Types of PVC Granules in Pipe Manufacturing

Rigid PVC Granules (PVC Granules in Pipes and Fittings)

Used primarily in the construction of water supply and wastewater pipes, rigid PVC granules provide the necessary rigidity and strength to the pipe structure.

Flexible PVC Granules

Flexibility is often a requirement for specific types of drainage pipes and garden hoses, and these are the typical applications for such pipes.

High-Impact PVC Granules

In scenarios demanding enhanced resilience, such as the transport of chemicals or high-temperature fluids in industrial pipes, these granules are the go-to choice.

Key Roles in Pipe and Fitting Manufacturing

Consistency and Quality Control

One of the most significant advantages of using PVC granules is the consistency they bring to the manufacturing process. Their uniform size allows for even melting and blending, leading to pipes and fittings that are uniform in quality and strength. This consistency is critical for ensuring that products meet the stringent standards required for construction and industrial applications.

Improved Production Efficiency

The granulated form of PVC significantly boosts production efficiency. Due to their small size and uniform nature, PVC granules flow easily through the machines, reducing clogs and improving the speed of the manufacturing process.

Customization (PVC Granules in Pipes and Fittings)

Different types of pipes and fittings require varying characteristics like flexibility, rigidity, or impact resistance.Manufacturers can custom-formulate PVC granules to achieve specific properties, enabling the creation of specialized products tailored for various applications.

Technological Advancements

Compounding Techniques

Advanced compounding techniques have made it possible to add various additives and fillers to PVC granules, thus enhancing their properties. For instance, anti-oxidants and UV stabilizers can be added to improve the longevity of outdoor pipes.

Automation in Manufacturing

The uniform nature of PVC granules is ideally suited for automated manufacturing processes. Automation not only increases the speed of production but also minimizes errors, ensuring high-quality end products.

Challenges and Considerations

Environmental Concerns

PVC is a synthetic material, and its production and disposal raise environmental concerns. However, research is ongoing to produce more eco-friendly PVC granules, including biodegradable and recyclable versions.

Cost Implications

High-quality PVC granules can be expensive, affecting the overall cost of the pipes and fittings. However, considering the long-term benefits like durability and minimal maintenance, the initial investment is often justified.

Conclusion

PVC granules play an indispensable role in the manufacturing of pipes and fittings. They offer a level of consistency, quality control, and efficiency that is hard to achieve with other forms of raw materials. Furthermore, technological advancements have allowed for the customization and enhancement of PVC granules, making them adaptable for specialized applications. While challenges such as environmental impact and cost remain, they are being actively addressed through innovation and research. As the construction and industrial sectors continue to evolve, the role of PVC granules in pipe and fitting manufacturing is likely to become even more significant, driving quality, efficiency, and sustainability in this crucial industry.